Maine Stair Company Wins People’s Choice Award

We’re excited to congratulate Maine Stair Company on winning Best Curved Stairway – Artisan and the People’s Choice Award at this year’s SMA Annual Conference and Staircraft Awards Competition! […]

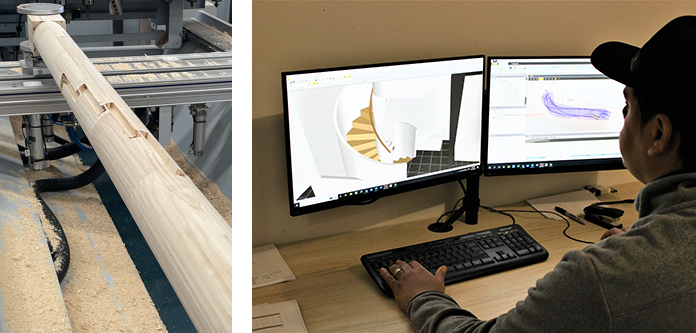

Staircom Pty Ltd is a family-owned business that offer a full range of products, from basic staircases to high-end designs. They started using the CAD/CAM software Staircon in 2017 to create programs for their two Homag 5 axis CNCs.

“The two best business decisions we’ve made; buying Homag equipment and buying Staircon software” says Damien Hunter, owner of Staircom.

The woodworking company Staircom started in 1999 with only four employees. Today it’s run by Damien and Brett Hunter, employing 23 full-time staff members, with a manufacturing facility in Melbourne covering 2400 m2. They are currently producing between 40 and 50 staircases a week, with projects ranging from multi-unit developments to high-end custom-made designs, Damien explains that:

“For our customers building multi-unit residential developments cost efficient solutions are essential, especially in today’s marketplace whereas the high-end designs generally require exacting detail in design, perfect manufacturing, and the ability to turn a customer’s concept into reality.”

They started out making just basic MDF staircases with turned timber balustrades. But the demand for more complicated designs using steel and stainless-steel components and even glass has since then increased. Damien says they’ve been keeping an eye on the Elecosoft software for some time:

“We first noticed Staircon software in 2014. Seeing Staircon develop over the following years, especially in the way it was able to display staircases in 3D, we watched it progress into a market leading product.”

Production efficiency and 3D capability

They decided to proceed with their purchase of Staircon in 2017, looking for software that could combine both greater production efficiency and better 3D visualisation capability.

“The way that we can create 5 axis WoodWop programs straight out of Staircon CAM software is amazing. It’s actually possible to design a staircase while onsite using Staircon, send the project to the office for processing and have the job ready to run on the CNC 10 minutes later. We also have an add-on module called export to 3D allowing us to share our 3D designs with customers on Sketchfab” Damien says.

Though their projects vary in size, Damien explains that their company takes pride in their consistent quality and ability to carry out projects from start to finish. With Staircon, they have been able to increase efficiency, especially when working with complicated componentry that can’t be done by hand.

“Since implementing Staircon we have been able to fine tune the whole manufacturing process which has allowed us to increase the number of stairs we make each week, and the amount of complicated products that we produce.”

“We are currently producing a complicated curved staircase like our Helical stair every 6 days on average, this wouldn’t be possible without Staircon software and our Homag CNC’s.”

Working with Elecosoft and looking ahead

When asked about their experience working with Elecosoft, Damien mentions the availability and quality of support, stating that:

“Elecosoft have been good to deal with since day one. Support has mainly been by e-mail up until now, but even still it always felt as if there was someone there to help and questions were never left unanswered. Now that a highly skilled member of staff has moved to Australia, there is full local support for the Australian and ANZ market.”

Since 2017, Staircom has increased their licenses, add-ons and found new ways to improve their business using Staircon. But Damien claims they are just getting started.

“Staircon has been able to keep up with our business and the way we are developing new ways of doing things. If you come up with a new idea or design, there’s a good chance that you will be able to do it in Staircon. We still have many more ideas on how to further develop our business in partnership with Staircon.”